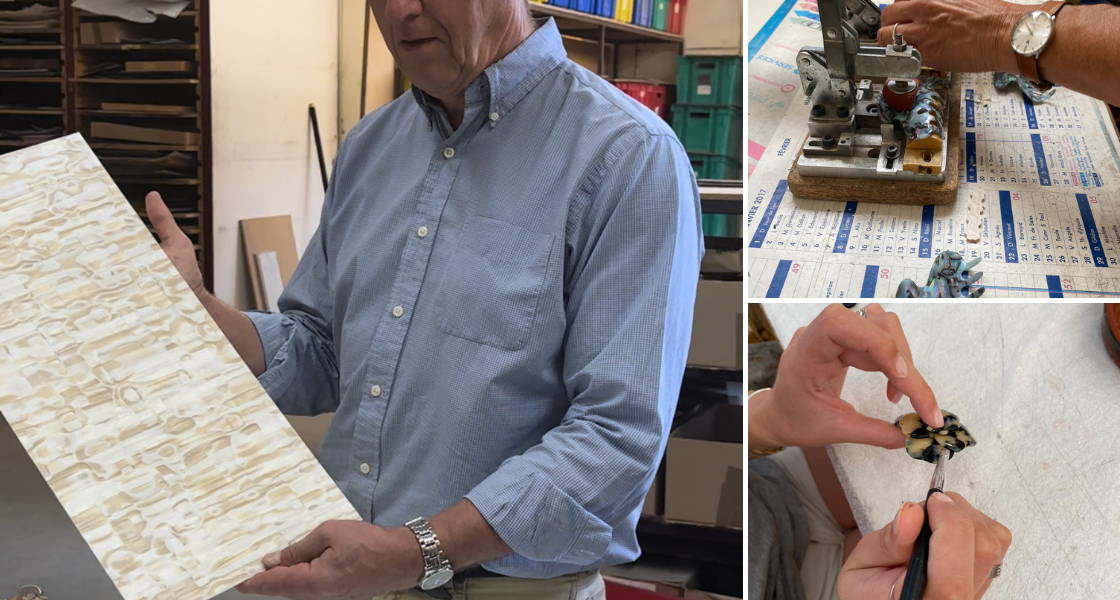

Step one: We choose the desired material

Our French Handmade clips are made from a material called cellulose acetate. Vast sheets of this super-strong, flexible material are ordered in directly from Italy, for a superior quality product. At this stage, the materials haven’t been dyed yet, and we're offered a selection of patterns and colours to choose from. Based on our extensive knowledge of talking to our customers on a daily basis, we pick the designs we think our customers will like and the company gets to work!

Step two: Cutting the material

Each French Handmade clip is then cut out using handheld lasers. The factory uses a 3D machine which allows them to carve deeper into the sheets of resin and carry out any engraving work that needs to be done. The pieces for the hair clips are all still flat at this stage of the creation process.

Step three: Forming the clips

It’s time to shape the clips! Each piece is dropped into 80-degree water to soften the material and allow each clip to be modelled. After the material has been softened, it is placed into a mould and then plunged into cold water to fix the final shape. This is a time-consuming operation with only one piece being made at a time. Using this method, only 80 headbands are made in an hour.

Step four: Polishing the clips

Polishing gives the clips their exceptionally smooth feel. The clips are placed into a sort of wooden box, or a cask, with different material beads inside. When the cask is shaken, these materials, ranging from wood to polypropylene to a soft granite, each give a different finish. According to the desire of the customer, clips can go through up to seven polishes across the differing casks, taking up to a week to create the perfect smooth finish!

Step five: Acetone soaking

Once the sanding is complete, the hair clips are soaked in acetone. Acetone makes the pieces shine and ensures the colour won’t fade.

Step six: Dying the materials

It’s finally time to give the clips their signature deep colouring. The company uses Pantone colour pickers to ensure we can choose the exact colour we want for our customers. Once a colour and design have been agreed upon, the pieces are coloured using a harmless, water-based, environmentally friendly dye.

Cellulose acetate is a very sensitive material which does not always react as expected to the dye. If a piece doesn’t match the desired colour, it is bleached white and the dying process begins again!

Step seven: Hand polishing

This step ensures that each clip is shined to perfection. Using chamois leather, each piece is buffed painstakingly by hand to ensure that no scratches remain.

Step eight: Completion

This stage allows any further customisation, like adding customer initials, or any further meticulous paintwork that can only be added by hand.

Step nine: Crystal Work

The clips are sent to a specialist facility to add our branding with a printing machine. This is where our logo gets added, with the reassuring words “handmade in France” which we believe should be on every clip you buy! At this stage, any Swarovski crystals are also glued on by hand, one by one to ensure they are secure.

Step ten: adding the hinge

Finally, the exceptionally strong steel hinges are fitted and the clips are ready for use.

Time for shipping!

When the clips are ready to ship, each clip is manually packed one by one. This allows for a final quality check, ensuring that all crystals are present and secure and the paintwork is perfect.

The clips are then sent directly to us, where you can find them right here on our website!

So, what do you think? Hopefully, this has given you a little insight into our quality French hair accessories, so that when you wear them you can enjoy knowing that you are wearing a truly luxurious piece which has been created with lots of love and care.

Want to know more? Why not read our other blog outlining more reasons why cellulose acetate hair accessories are superior to plastic clips.